Taming the Wild Bytes and Turning Them into Insights

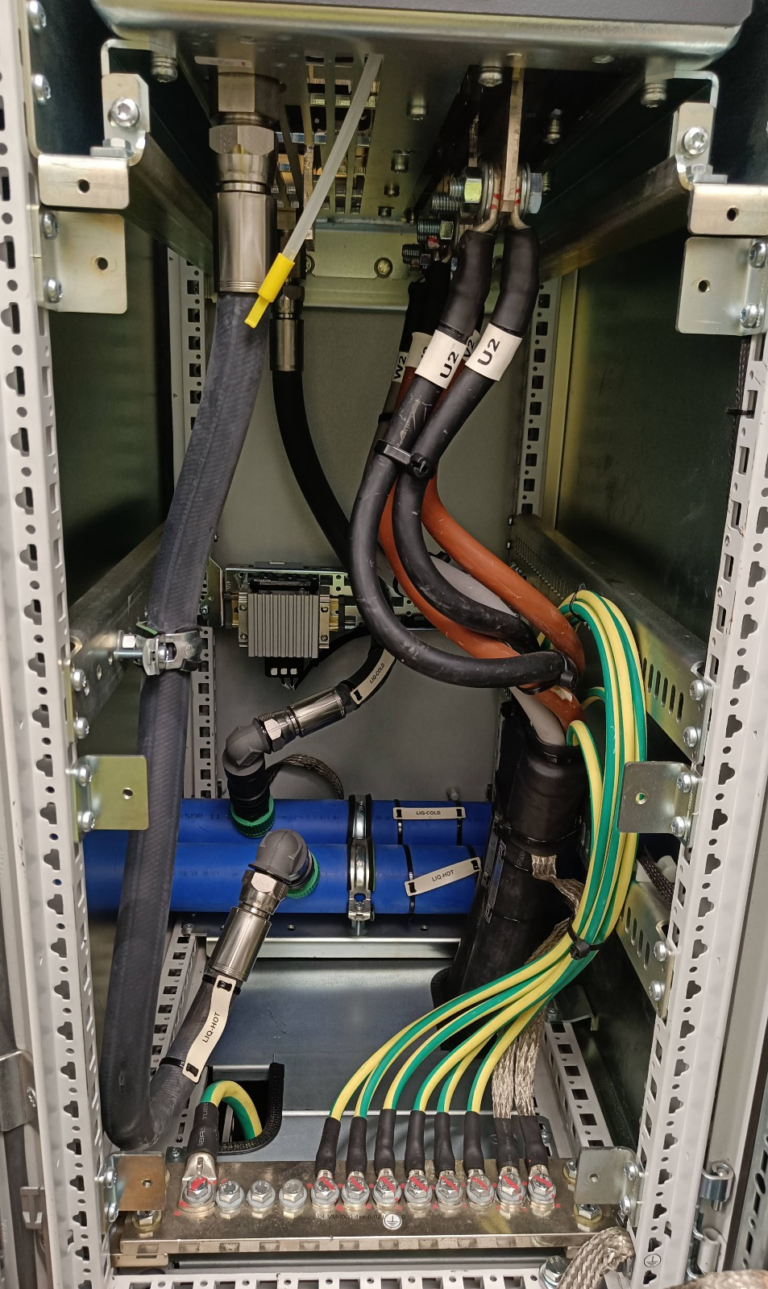

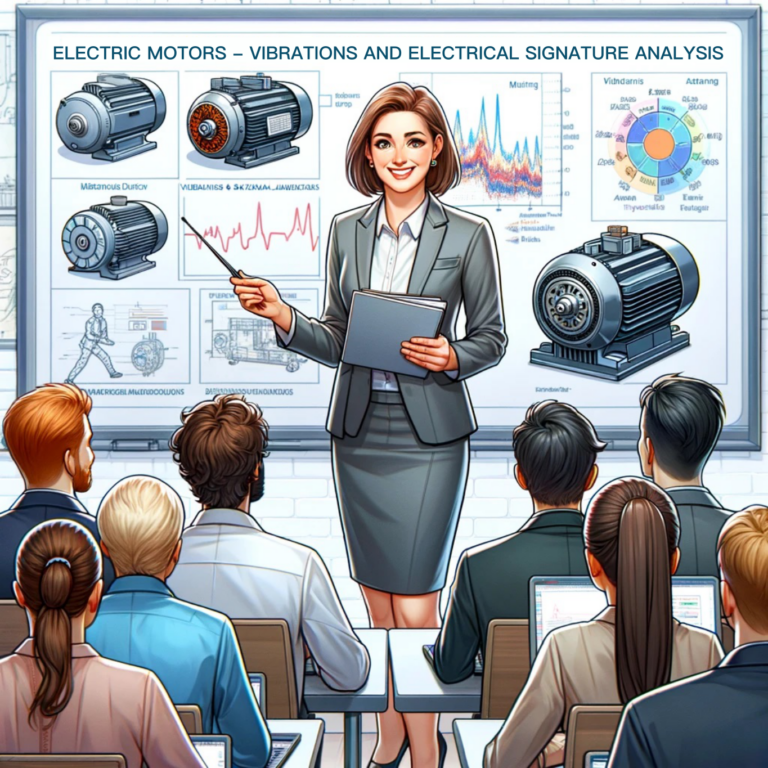

Machines are constantly sending out signals about how they are working, just like how humans send out signals about their health. These signals can be things like temperature, noise, or vibrations. By doing something called a Failure Mode Effect and Criticality Analysis (FMECA), we can figure out which signals and patterns of signals might mean that there is a problem with the machine. Data is useful if it can help us understand the condition of the machine.

For example, if we want to know if a machine’s bearings are working well, we might use vibration monitoring to check for any problems. Some analysis techniques can even detect small problems with bearings early on. But if the problem is something else, like the machine is too hot because of a grease problem, then the vibration data might not be as helpful. In that case, we might need to use other techniques, like thermal analysis, to understand the problem. Having a true insight means having the right information to understand a problem. This can only be achieved by collecting the appropriate data for the issue at hand.