Results of our recent challenge!

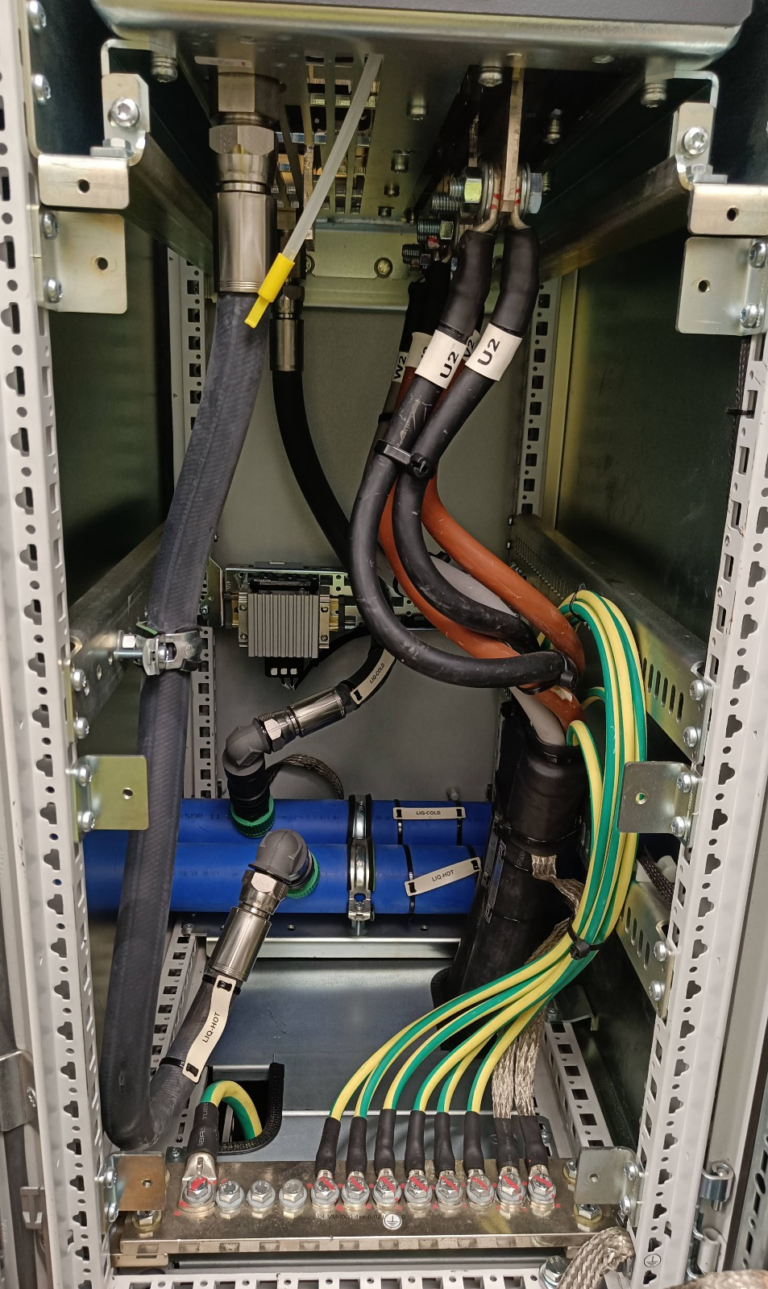

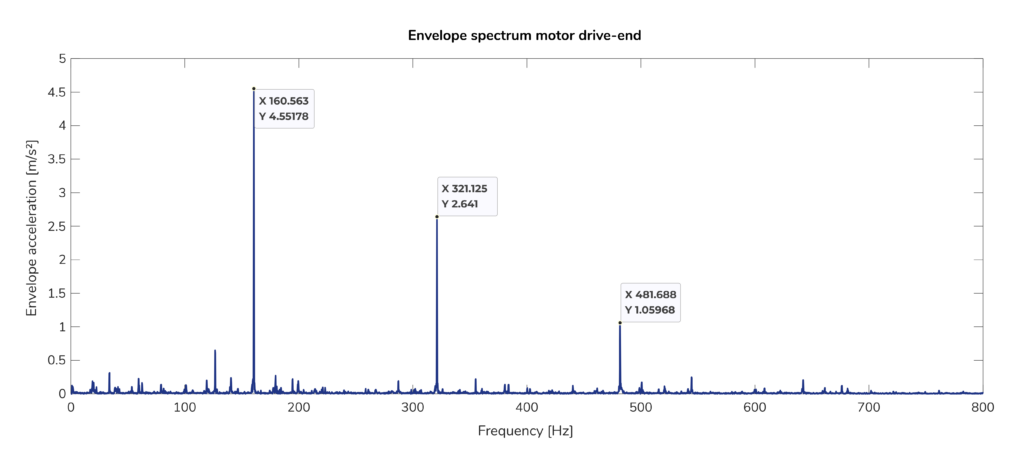

Two weeks ago, we initiated a challenge on LinkedIn involving a 160 kW motor with an unconventional spectrum within its envelope. The question was about an envelope spectrum measured on a 160 kW induction motor with a nominal speed of 1487 RPM and a max operating speed of 3000 RPM, but the process is set at 2400 RPM. The motor is equipped with rolling element bearings.

Upon measuring acceleration close to the drive-end bearing, we observed an envelope spectrum with distinct peaks, including a fundamental frequency and clear second and third harmonics. What could explain this type of pattern?

1. Single point failure on the outer race of the drive-end bearing

2. Single point failure on the inner race of the drive-end bearing

3. Forcing frequencies of the load

4. Sidebands of the switching frequencies

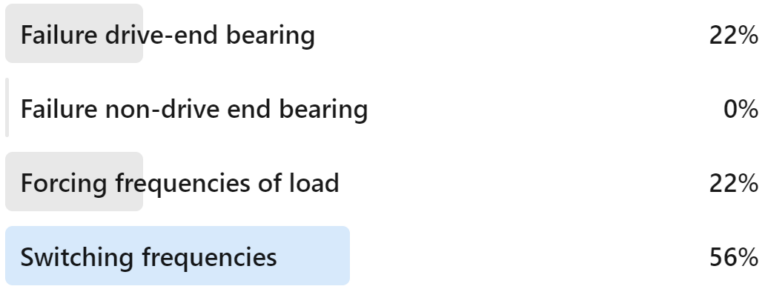

Here are the responses:

We’re thrilled to note that the majority of our followers made accurate guesses! When dealing with envelope spectra, it’s crucial to exercise caution. They result from signal transformations, including the use of a bandpass filter. The filter settings can significantly impact the outcome. In cases where frequency shifts occur due to a Variable Frequency Drive, they may fall within the filter range, contributing to the envelope spectrum. That’s precisely what unfolded in this scenario!