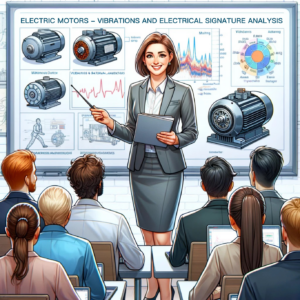

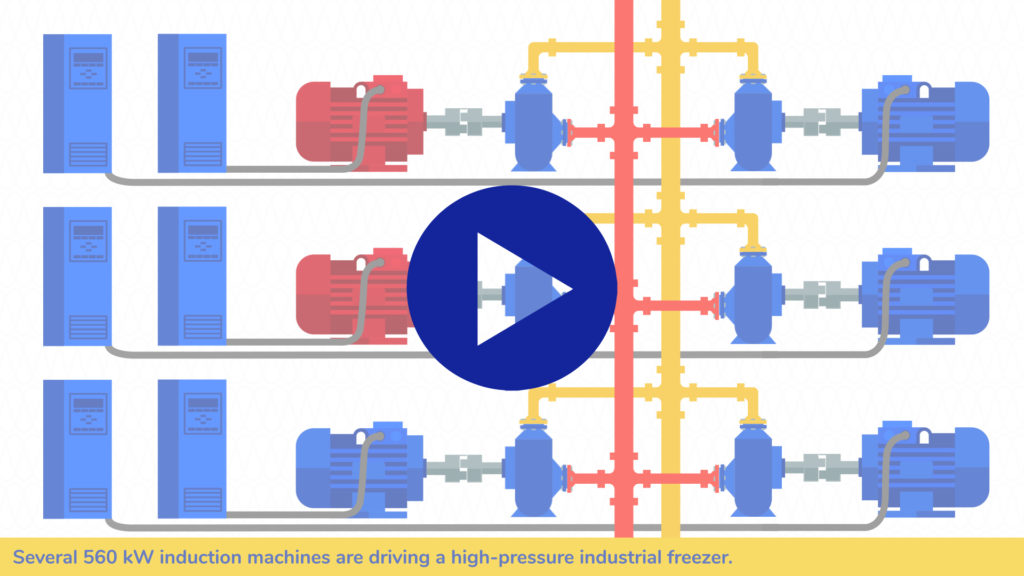

Case video: Capturing failure mechanisms

Analyzing motor currents (MCSA) does not only reveal failing components, it also elucidates the root cause of the failure modes. Two critical 560 kW induction machines experienced monthly reoccurring bearing failure. ORBITS found the root cause and prevented future damage by implementing a proactive solution. Watch our case video!

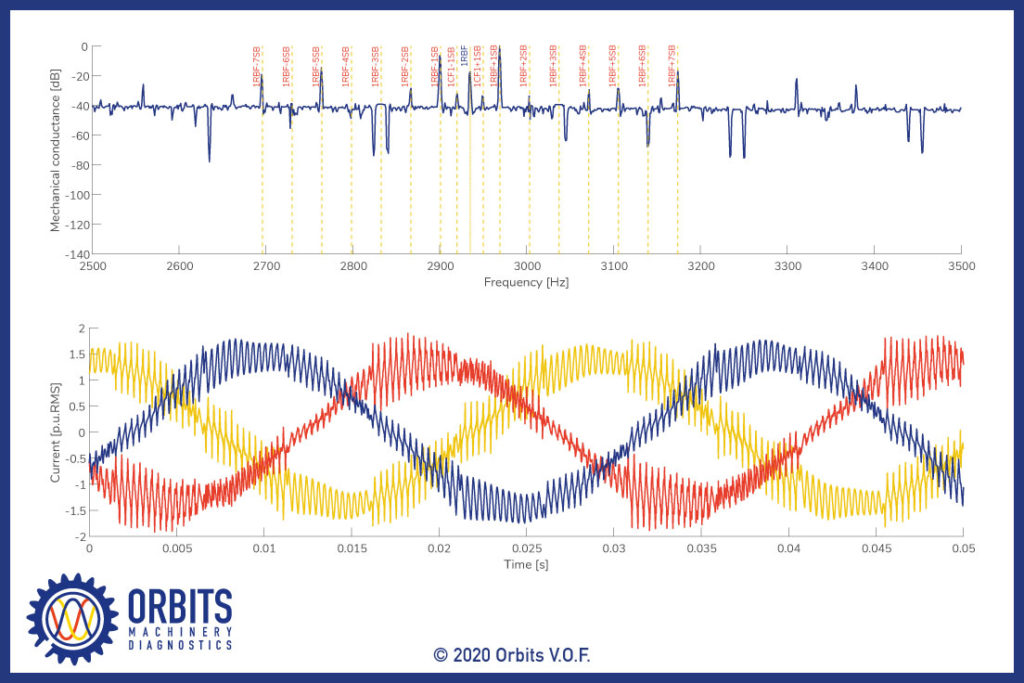

Case: Bearing failure

Detecting bearing failures through stator current measurements (MCSA) seems quite tricky. However, using electrical signals, we are able to construct a crystal clear view of the rotor position relative to the stator housing during operation. In the following case, we detected a cocked bearing just after an overhaul of a 200 kW compressor (small cage […]

Case: Gear problem

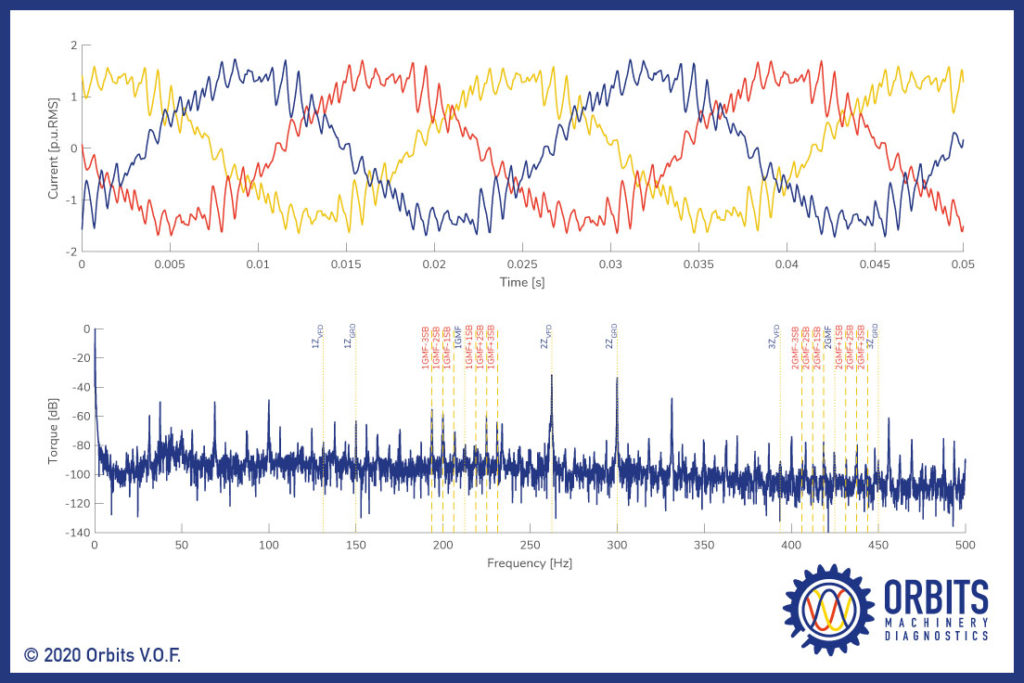

Using safely captured voltage and current signals of an electric machine, the instantaneous electromechanical torque can reveal interesting information regarding the condition of the entire drivetrain. In a recent case, we avoided an unexpected failure by detecting a worn-out gear on the low-speed output shaft (378 RPM) of a gearbox driven by a 250 kW […]