Striking the Right Chord: Bump testing in machinery diagnostics

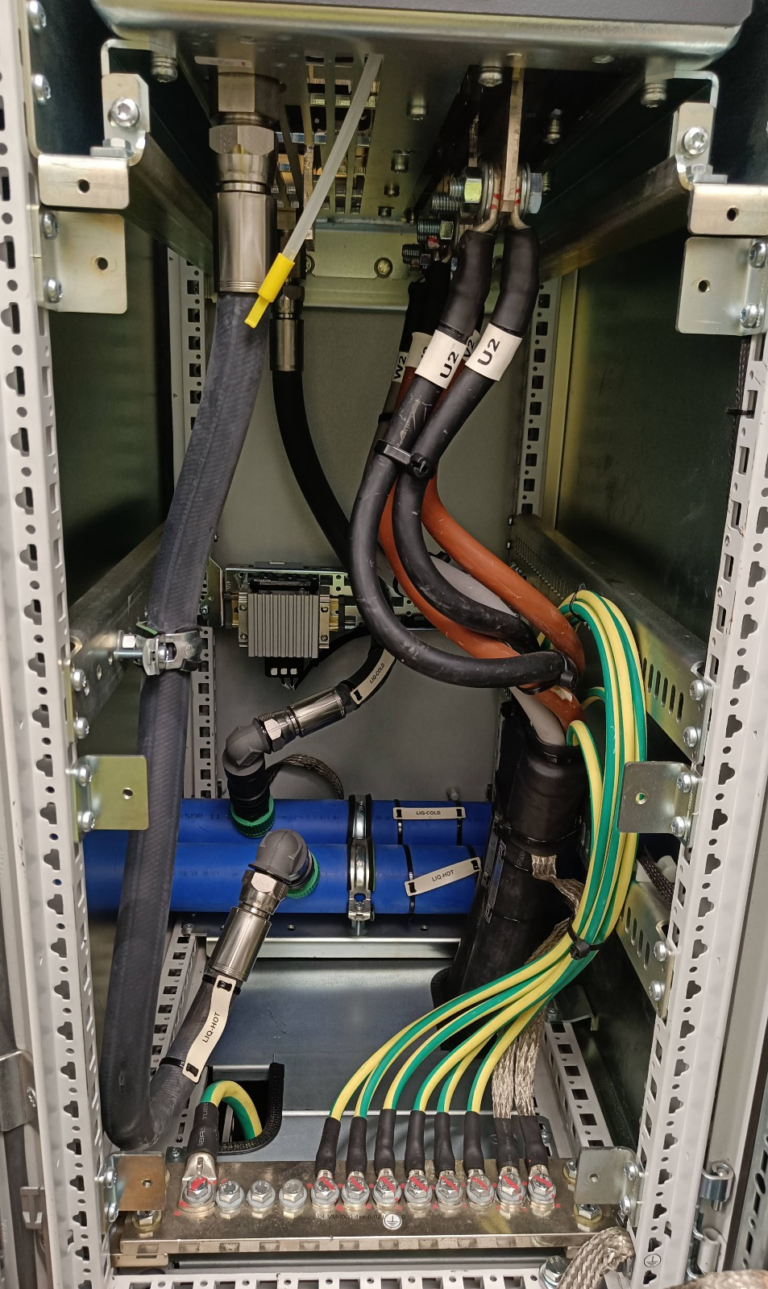

Resonance frequencies play a crucial role in the health of rotating machines. While bump testing and impact testing share a similar concept, they differ in their approach. Bump testing focuses on only identifying resonance frequencies by exciting multiple frequencies simultaneously, whereas impact testing is commonly used for modal analysis.

During an impact test, an impact hammer equipped with a force sensor is employed. This allows the measurement of frequency response functions, which reveal the force-to-response ratio in the frequency domain.

On the other hand, a bump test is a response-only method. The force generated by the hammer or impacting device is not measured directly, assuming it produces a signal rich in frequencies. This means that any available hammer or even a hard tool capable of generating an impact can be used. However, it is important to note several considerations.

Since the real force applied to the structure remains unknown, it can only be assumed. Estimating the appropriate force can be challenging, as using a larger hammer tends to excite fewer frequencies, resulting in other responses. Additionally, it is crucial to understand that the presence of resonance frequencies does not necessarily indicate problems with your asset. It is advisable to complement this test with operational measurements to gain a comprehensive understanding.

Incorporating bump testing into your analysis toolkit provides valuable insights into resonance frequencies. Remember to consider the nuances involved, leverage operational measurements, and choose the most suitable approach for your specific needs.