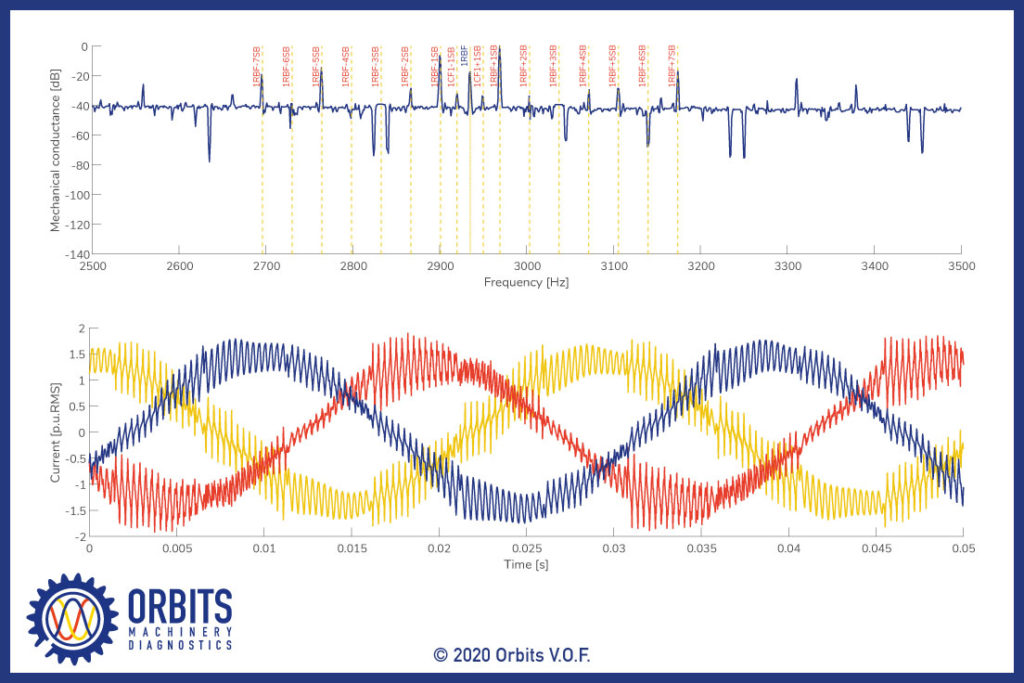

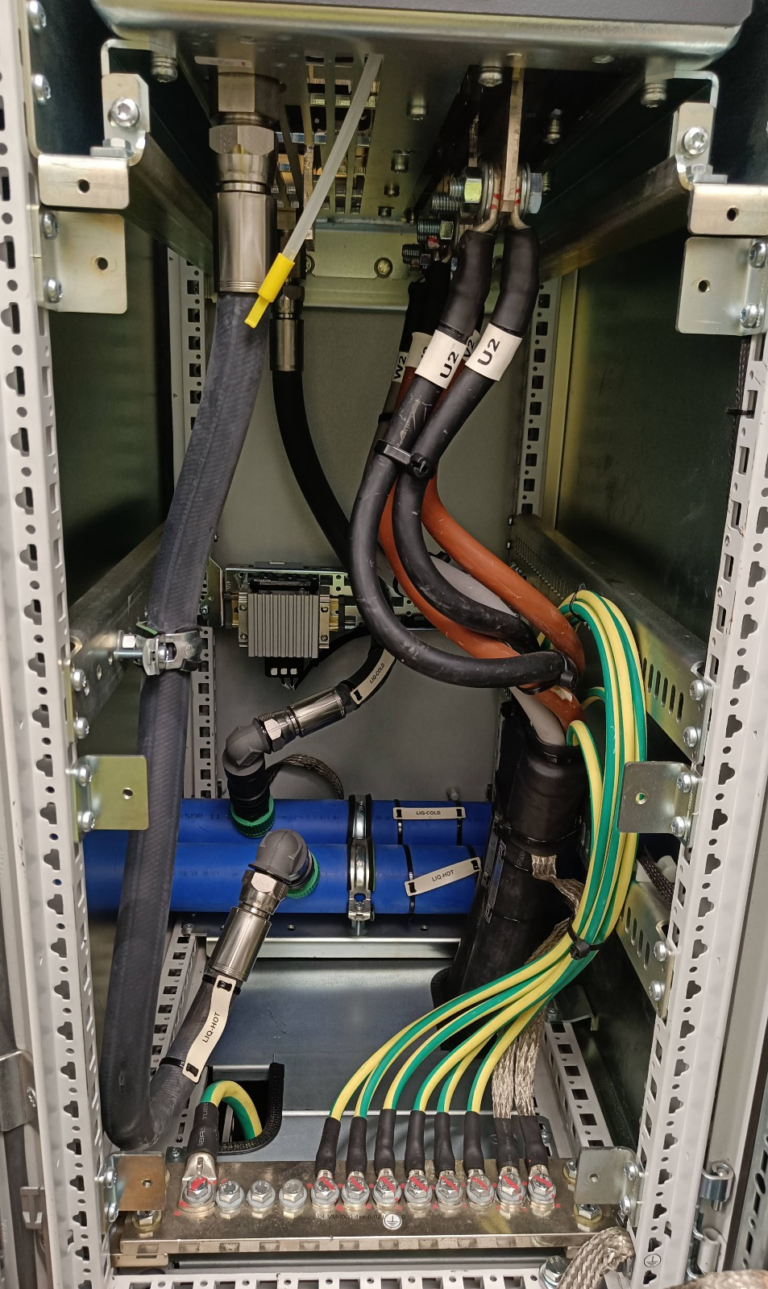

Detecting bearing failures through stator current measurements (MCSA) seems quite tricky. However, using electrical signals, we are able to construct a crystal clear view of the rotor position relative to the stator housing during operation. In the following case, we detected a cocked bearing just after an overhaul of a 200 kW compressor (small cage frequency sidebands around the rotor bar passing frequency). The machine was revised again before abrupt failure and collateral damage could arise.

Do you want to get your machines diagnosed? Do you want to learn more about MCSA or other advanced diagnostic techniques? Call us today and we will be at your doorstep tomorrow!